-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: aceally18350222213

Wechat: aceally18350222213

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

Wechat: aceally18350222213

Wechat: aceally18350222213

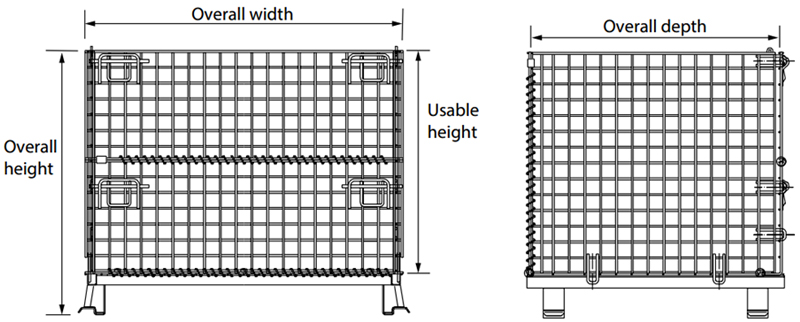

Collapsible wire mesh container has a low weight-to-load ratio, which means more stock and less container is moved. Also, the contents can be seen easily, even when the storage container baskets are stacked several units high.

Stackable and collapsible, our rust-resistant galvanized wire mesh container is durable, portable, self-cleaning and shippable. The process of galvanizing the wire mesh after welding ensures a lifetime of rust resistance. Stainless steel wire mesh containers reduce costly product damage associated with bulk stacking, and they offer better space utilization, product identification, and easier bulk material handling.

|

|

|

Flat clasp structure |

Latch structure |

|

Strengthening the connection strength of the foldable wire mesh container |

Ensuring that the door can be opened when the containers are stacked so as to make it convenient to put in or tack out items |

|

|

|

|

|

|

|

Limit wire structure |

Square cup foot |

|

Guaranteeing the stability during stacking |

Special supporting leg structure for secure stacking |

|

Optional designs & accessories |

|

|

|

|

|

Dolly |

Castors |

|

Allows for easy movement of containers without the use of a forklift |

A quick solution to mobilize containers without interfering stackability |

|

|

|

|

|

|

|

Divider |

Security lid |

|

Front-to-back or left-to-right, for multiple products to be stored in one container |

Secure for parts in storage or transit |

1. It is made of high-quality steel Q235 which is cold-hardened and welded. It has high strength and large loading capacity.

2. The product specifications are uniform, the capacity is fixed, the goods are stored at a glance, and it is easy to inventory.

3. The surface is galvanized, beautiful and anti-oxidant, and the service life is up to 10 years.

4. It adopts international standards and can be used with containers to effectively improve space utilization.

5. It can be stacked on top of each other to achieve three-dimensional storage.

6. Surface environmental treatment, health immunization, turnover, storage, and recycling which do not pollute the environment.

7. Efficient operation can be carried out with equipment such as forklifts, ground cattle, elevators, and cranes.

8. The folding structure has low recycling cost and is an alternative to wooden crates.

9. Wheels can be installed at the bottom, making it easy to turn around inside the factory.

10. Open and fold in just 5 seconds, stack them when not in use, saving floor space.

Note: Wheeled storage cage (standard storage cage without casters, casters are additionally fitted)

Warehouse, logistic, recycling industry, temporary storage, transportation, sorting and storage of raw materials, semi-finished products and finished products.

| Model No. | Exterior Dimension | Wire Guage | Grid Size | Loading Capacity | Loaded in 1x40'GP |

|

|

LxWxH(mm) | mm | mm | kg | sets |

| W-1 | 1030x840x850 | 6 | 50x50 | 1300 | 470 |

| W-2 | 1230x1040x890 | 6.2 | 50x50 | 1700 | 320 |

| W-3 | 1030x840x500 | 6 | 50x50 | 800 | 470 |

| L-1 | 1030x840x850 | 6 | 50x50 | 800 | 470 |

| L-2 | 1230x1040x900 | 6.2 | 50x50 | 1200 | 320 |

| K-1 | 830x530x550 | 4.8 | 25x50 | 450 | 700 |

| E-1 | 1030x840x850 | 6.2 | 50x50 | 1200 | 320 |

| S-1 | 1230x1040x950 | 6.2 | 50x50 | 1700 | 320 |

| Material | Mild steel Q235 | ||||

| Application Area | Warehouse, logistic, recycling industry | ||||

| Finish | Zinc/hot dip galvanized/powder coating | ||||

| Remark | Customized or OEM support | ||||