-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Metal galvanized storage pallet cages

Time:4/15/2019

Time:4/15/2019 1306

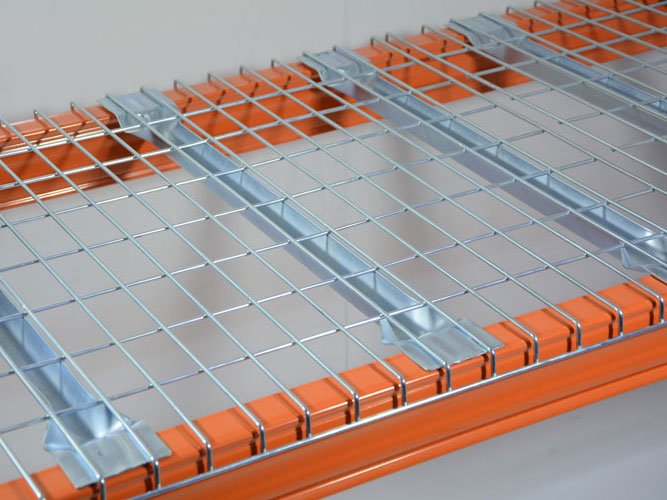

1306Metal Storage Cages are essentially a wheeled truck/trolley base with a metal mesh/cage vertical storage area on top of them. Since they already have wheels/castors and can easily be pushed and maneuvered in and out of supply vehicles, and easily moved to from areas where goods are loaded and unloaded, they eliminate the need for some of the expensive and specialized transportation which is normally used with pallets e.g. Forklifts. Metal galvanized storage pallet cages can also be known by other names associated with their function and appearance e.g. A package trolley, crate trolley, roll container or more merely a distribution trolley.

As mentioned before, where the distribution of smaller goods e.g. For retail or for parcels and a massive selection of others, the nearest practical choice is using pallets - the wooden pallet, the Euro pallet or gloomy pallet. Such pallets are frequently used, and among the reasons for this could be their rather low purchase and rental prices, wide accessibility, and the widespread experience of handling them in the distribution industry. They do have some particular drawbacks that might have a negative impact on the goods being transported, push the costs and reduce the competitiveness of distribution businesses. Wooden pallets, for instance, aren't especially eco-friendly because they're made from wood, and since they're rarely returned after one use, there's a constant need for more wood.

This one-off use may also contribute to high costs. Wooden Pallets frequently need to be fumigated to avoid infestation and also contamination. They may also lead to the harm of some merchandise stacked on those due to overhang, or harm from the vehicles used to move the pallets. The pallets themselves may also be easily damaged by sticking to a fairly low height e.g. 1 meter. These metal wheeled trucks/trolleys eliminate the need forklifts and provide much more protection of and safety for the goods stacked inside them.

Their use of vertical space and also uniformity of depth and width because of their defined sides and also lack of product overhang bring numerous advantages and benefits. These include better use of space in transport, and also allowing the use of shelves inside the cages thereby reducing the harm to goods and again making more parsimonious use of space. The metal mesh Structure makes roll cages more resistant and stronger than pallet alternatives. Even though the metal sides limit the size and positioning of some items, and the metal construction can occasionally make their use noisy, these potential drawbacks are more than compensated by the advantages already mentioned.