-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/21/2025

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Aluminum Pallet - Leader of Light Pallet

Time:9/4/2019

Time:9/4/2019 1121

1121

Aluminum pallet, as its name implies, is made of aluminum alloy, no other material accessories. Of course, in addition to the tray several anti-skid pads supporting the bottom of the foot.

Aluminum pallets are known for their lightweight nature. An aluminium tray with loading capacity of 1 ton can be easily picked up by an adult.

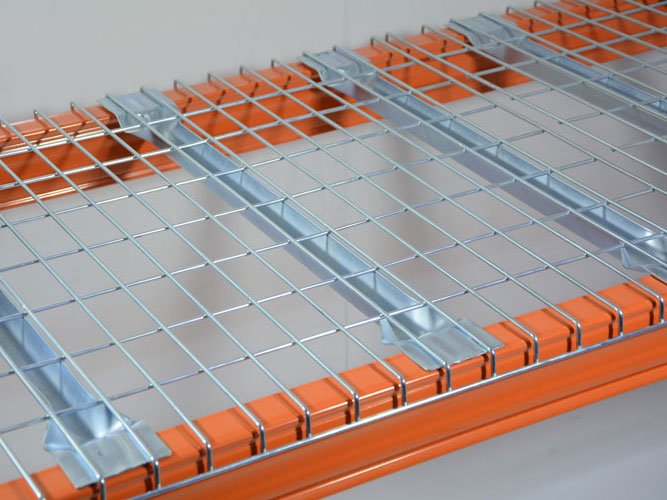

The bearing and supporting parts of all-aluminium pallet are all connected and combined by aluminium alloy. The supporting beams are I-shaped aluminium profiles.

In the supporting beams, the upper and outer sides of the two supporting beams located at both ends are fixed with bearing beams and suspension brackets. The bearing beams are extended vertically from the upper and outer sides of the supporting beams, and the long sides of the bearing beams are two.

The end is set on the sealing plate of the bearing beam, and the suspension belt supporting plate extends vertically downward from the upper outer side of the supporting beam.

Compared with related technologies, this new type of all-aluminium pallet has good flexural performance because the supporting beam is I-shaped aluminium profile.

When loading heavy goods on the rack track, even if only the two ends of the supporting beam are pressed on the rack track, the middle of the supporting beam is suspended, and the disturbance value of the supporting beam is still low, which improves the coefficient safety.

For more information about aluminum pallets price, please contact aceally4@aceallygroup.com