-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Causes and treatment of warehouse rack deformation

Time:6/11/2021

Time:6/11/2021 1246

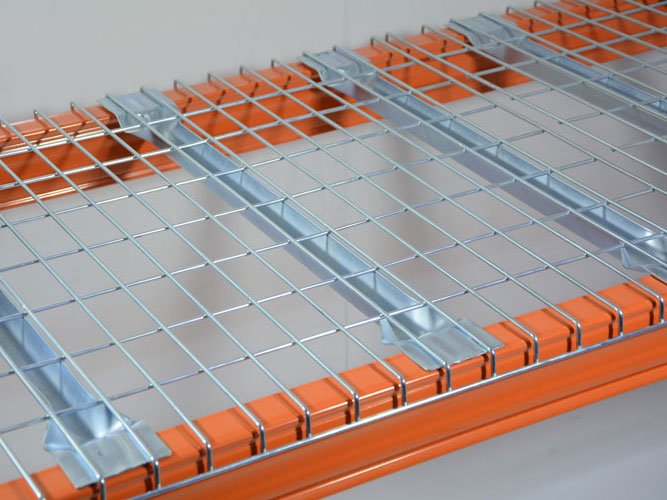

1246The warehouse rack is an important link in the distribution of warehousing materials. Warehouse management is to realize the integration of the logistics process. Therefore, under the pressure of improving service level, reducing inventory, saving time, and minimizing cost, warehouse management is obviously more and more important. But how can enterprises avoid the deformation caused by various factors in the use of storage racks? How to deal with the deformation?

1、 The causes of warehouse rack deformation are as follows:

1. The placement of goods exceeds the layer load of the warehouse racking system. Generally, when the storage rack is purchased, the warehouse rack factory will design the maximum bearing capacity of the rack according to the layer load of the stored goods. If in use, the storage capacity of the shelf exceeds the maximum bearing capacity, which will lead to the deformation of the rack.

2. The uneven weight distribution of goods will also cause the deformation of warehouse racks; If when placing goods, the weight of each layer of goods is concentrated in the middle part, and there is no layer load weight on both sides, it will certainly cause the shelf deformation.

3. Improper use of handling equipment operation, warehousing staff in the use of handling equipment to operate goods, improper operation, resulting in forklift hit the shelf, resulting in storage shelf deformation.

1. Select high-quality steel;

2. The goods are evenly distributed on the warehouse racks to avoid the goods being placed in the same position;

3. Warehosue storage rack design must follow the basic principles of design.