-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

How to identify the quality of wire containers?

Time:10/8/2019

Time:10/8/2019 915

915With the rapid development of modern industry, wire container has more and more functions. The wire mesh container can be placed in the warehouse, assembly line or stacking.

The wire container with wheels can be easily and quickly turned around in the workshop. And it can also be equipped with traction on the cage, with traction machinery attached in front, so that the mesh containers can be connected like a small train to freely shuttle between the warehouse and the workshop.

So, do you know how to identify the quality of collapsible wire containers?

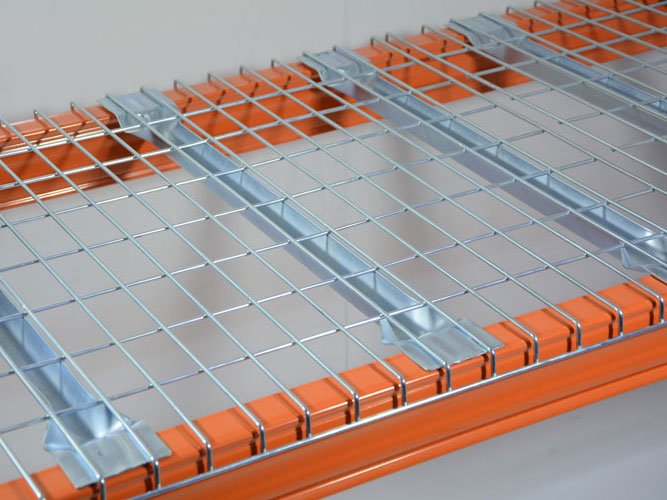

Firstly, the material of mesh containers should be up to standard, and the welding of mesh and mesh container base should be firm. There must be no desoldering or missing welding.

And then the carrying capacity of collapsible wire container is strong, which is basically high-speed wire plus channel steel. The thickness of channel steel determines the strength of collapsible wire containers.

The galvanized thickness on the surface of wire mesh containers shall be no less than 8um, smooth, without spot, burr and scratch marks.

The casters of wire mesh container has high flexibility. If the warehouse is not large enough, the turnover of goods will be affected.

Mesh storage containers in the manufacturing industry has gradually replaced the traditional wooden packaging, with the development of logistics and the use of mechanization, the cost has been more and more attention to the enterprise. Collapsible wire container also plays a role in promoting the development of enterprises.