-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

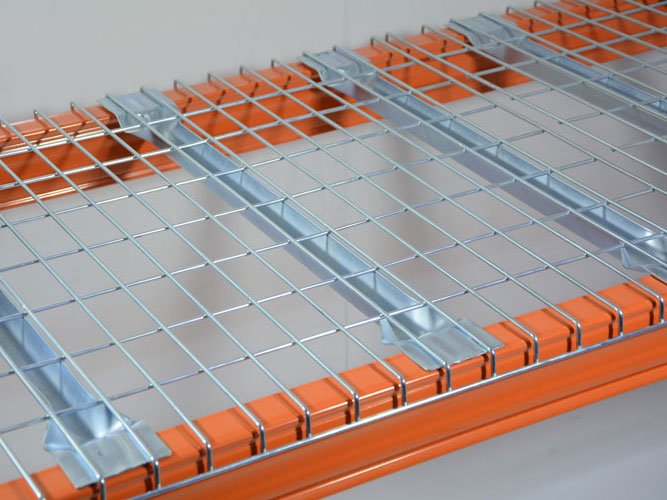

Tips of the use of galvanized steel pallets you should pay attention to

Time:5/20/2019

Time:5/20/2019 1245

1245The correct use of industrial galvanized steel pallets should make the goods packaged in combination codes on heavy duty steel pallets and properly bundled and wrapped so as to facilitate mechanical loading and unloading and transportation, so as to meet the requirements of loading, unloading, transportation, and storage.

- Loading capacity

The weight of each galvanized steel pallet shall be less than or equal to 2 tons. In order to ensure safety in transit, the weight of the goods should not exceed two-thirds of the width of the pallet.

- The ways of placing goods

According to the type of goods, the quality of the goods on the pallet and the size of the steel pallet, the way of placing the goods on the pallet is reasonably determined. The utilization ratio of the bearing surface area of steel pallets should generally not be less than 80percent. For pallet goods, the following requirements are required:

- 1. Hard cuboid goods such as wood, paper, and metal containers are packed in single or multiple layers of interlaced yards stretched or shrinkable film.

- 2. Paper or fiber goods are placed in multi-story yards and sealed with straps.

- 3. Sealed metal containers and other cylindrical goods are placed in single or multi-story yards, and wooden cargo covers are reinforced.

- 4. Paper products and textile goods that need to be protected against moisture and waterproofing should be placed in single or multi-layer staggered yards. Stretching or shrinking film packaging should be strengthened with angular support and cargo cover and partition.

- 5. One-way or multi-story yarding of fragile goods, adding wooden supporting partition structure.

- 6. Cylindrical metal bottle containers or cargo is placed vertically on a single layer to increase the reinforcement structure of cargo frames and slabs.

- 7. Multilayer staggered compaction yard for bags.