-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:4/14/2025

-

Time:4/8/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Wire mesh storage containers are the storage and transportation solution for modern industries

Time:3/24/2025

Time:3/24/2025 100

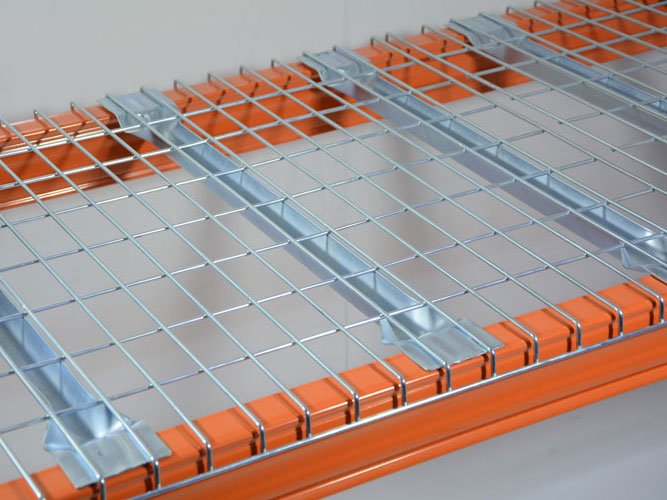

100In today’s fast-paced industrial landscape, efficiency, durability, and adaptability are critical for businesses aiming to optimize their operations. Wire mesh storage containers have emerged as a game-changer for industries ranging from manufacturing and logistics to agriculture and retail. These versatile storage and transportation units offer a blend of strength, functionality, and cost-effectiveness, making them indispensable for businesses worldwide. Wire mesh storage containers are the ultimate storage and transportation solution for modern industries. Let’s explore why wire mesh storage containers are a must-have for your organization.

1. Unmatched Durability for Heavy-Duty Use

Constructed from high-quality steel, wire mesh storage containers are built to withstand rigorous industrial environments. Whether you’re handling automotive parts, machinery components, or bulk agricultural products, these containers resist corrosion, impacts, and extreme weights. Their welded mesh design ensures structural integrity, even under repetitive loading and unloading cycles. Unlike plastic alternatives, wire mesh storage containers won’t crack or warp, offering a long-term solution that reduces replacement costs.

2. Versatility Across Industries

Wire mesh storage containers are designed to adapt to diverse needs.

Manufacturing & Assembly Lines: Perfect for organizing tools, parts, and work-in-progress materials.

Warehousing & Logistics: Facilitate efficient stacking and retrieval of goods, compatible with forklifts and pallet jacks.

Agriculture & Food Processing: Allow airflow to preserve perishables like fruits and vegetables, while withstanding moisture.

Retail & E-commerce: Ideal for displaying products or managing inventory in distribution centers.

Their collapsible or foldable variants further enhance space efficiency when not in use, a feature particularly valuable for businesses with limited storage areas.

The open-mesh structure provides full visibility of contents, simplifying inventory checks and reducing errors. This transparency is crucial for quality control and fast-paced operations. Additionally, the design promotes airflow, preventing moisture buildup and ensuring goods remain dry and fresh—critical for industries like pharmaceuticals or food storage.

4. Space Optimization and Cost Savings

Wire mesh storage containers are stackable, maximizing vertical storage space in warehouses or transport vehicles. Their uniform dimensions allow seamless integration with automated systems, reducing handling time. By minimizing product damage during transit, they also lower waste and associated costs. Over time, these efficiencies translate into significant savings.

5. Customizable to Your Needs

No two businesses are alike, and wire mesh storage containers can be tailored to meet specific requirements. Options include:

Adjustable dividers for compartmentalization.

Reinforced bases for heavier loads.

Special coatings (e.g., powder coating) for added corrosion resistance.

Custom sizes, mesh densities, and door configurations.

Why Choose Us?

As a leading manufacturer and exporter of wire mesh storage containers, we combine cutting-edge technology with stringent quality control to deliver products that exceed global standards. Our containers are ISO-certified, ensuring reliability for your most demanding applications. With competitive pricing, bulk order discounts, and OEM services, we empower businesses to streamline operations while cutting costs.

Take Action Today!

Upgrade your storage and logistics strategy with wire mesh storage containers that deliver unmatched value. Contact us now for a customized quote or to request samples. Let us help you build a smarter, more efficient workflow!