-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

Wechat: a18350222213

Wechat: a18350222213

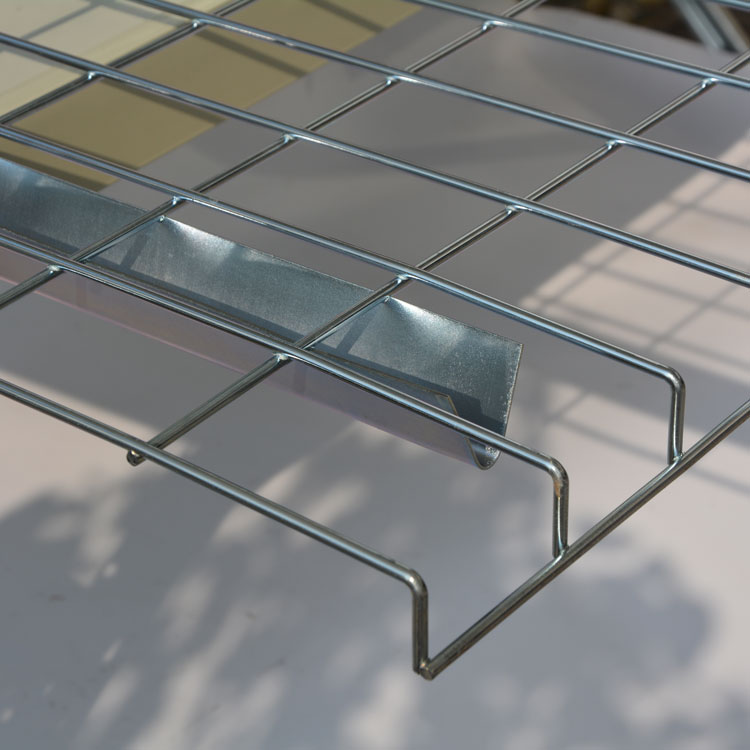

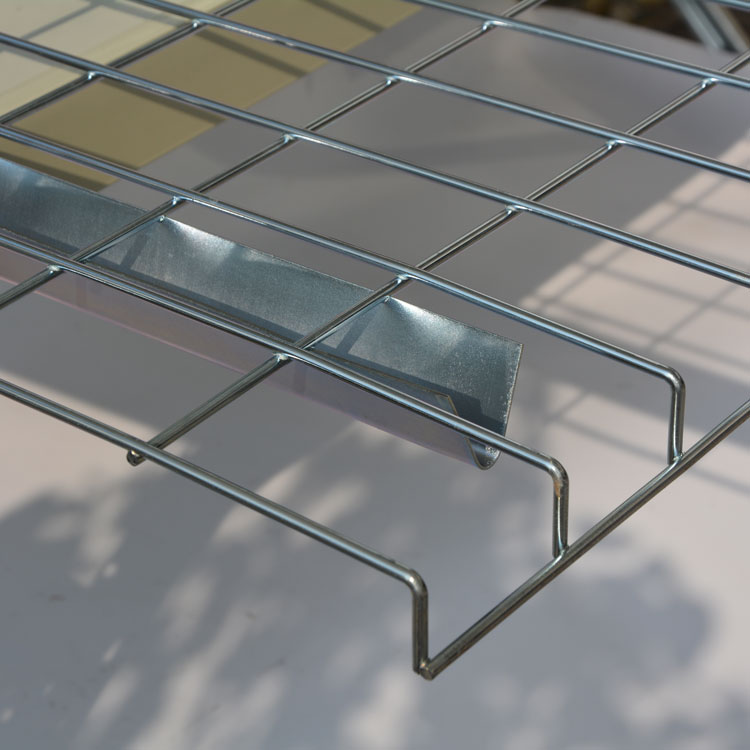

The wire rack decking size is usually customized according to the specifications of pallet rack, and the mesh decks production styles are different with different requirements of load-bearing capacity.

The U channel welded wire mesh decking panels are welded by cold drawing wire and U-shaped material. It is an ideal substitute for pallet shelves when laminates cannot be used. Grid welded wire mesh decking panel is a necessary match for pallet shelves.

According to the weight of the pallet rack, different meshes, wire diameters and number of supports are selected.

According to the shelf overlay design, the bottom plate has three or four U-shaped shelves mesh special reinforcing bar welding, can also be a rectangular tube.

The load-bearing capacity of each mesh fluctuates between 200 and 2000 KGS. The products conform to international environmental protection regulations.

1. Visualization is easy to manage, mesh laminates are firm, bearing capacity is strong, and bulk cargo is easy to clean storage.

2. Storage of cargo carrying 1-3T.

3. Mesh-type laminate design to prevent objects falling from the sky.

4. Strong wire is used for butt welding, the bottom is strengthened by U-shaped channel steel welding, and the structure is stronger.

5. With forklift truck, trolley, hydraulic pallet truck and other equipment, it can be applied to transportation, handling, loading and unloading, storage and other logistics links.

6. Comparing steel laminates with heavy shelves, it can save cost and place firmly.

7. Durable: 100% recycling with recycling benefits 8, lighter, stronger and cheaper than wooden pallets.

Packaging of Wire Mesh Decking